- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

Cement

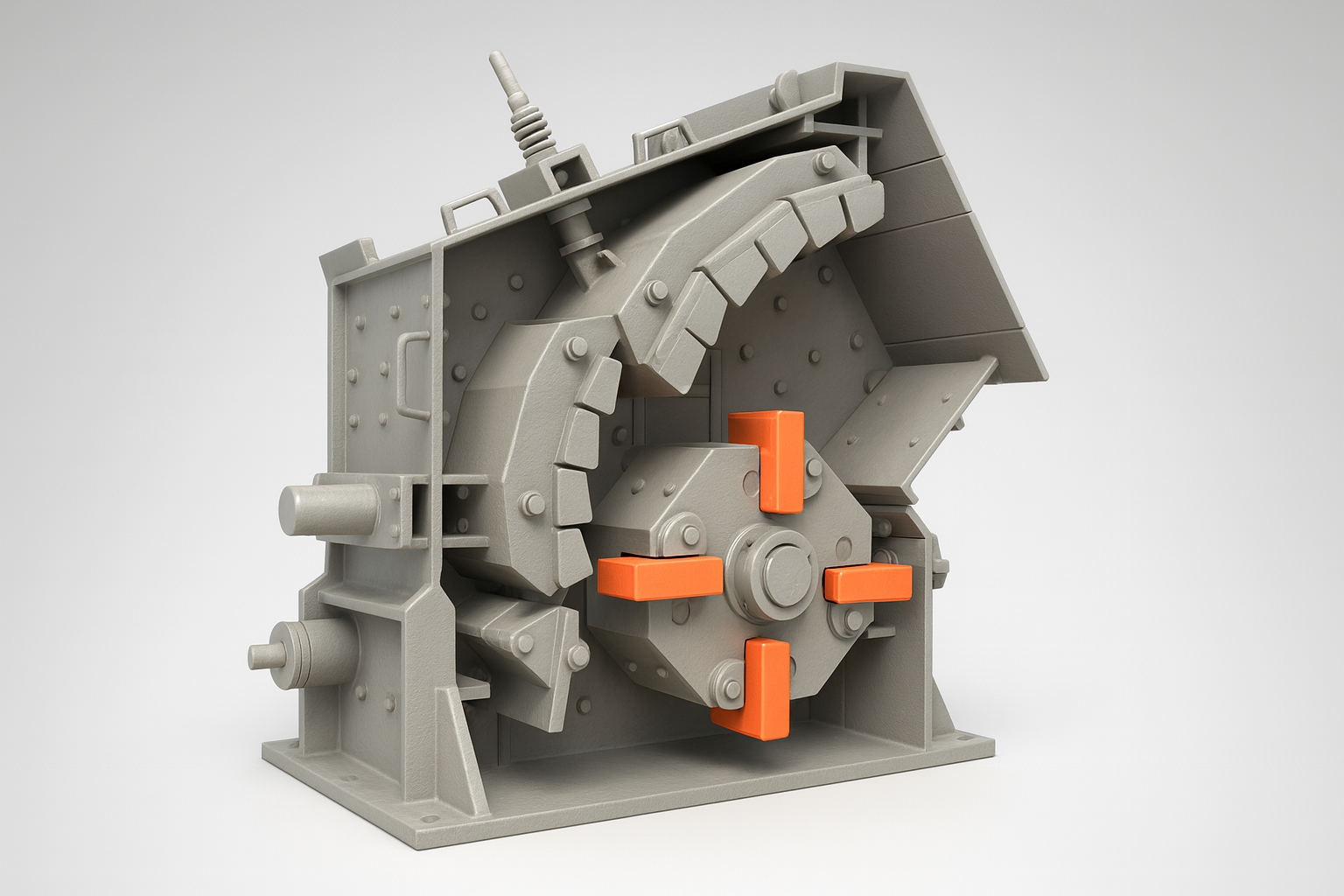

Wear protection for crushers and impact zones handling abrasive limestone.

Limestone crushing areas face heavy impact, gouging, and high abrasion from large and fine particles. Arcoplate provides superior impact resistance and extended life in crusher inlets, discharge chutes, and impact plates, reducing frequent liner replacement.

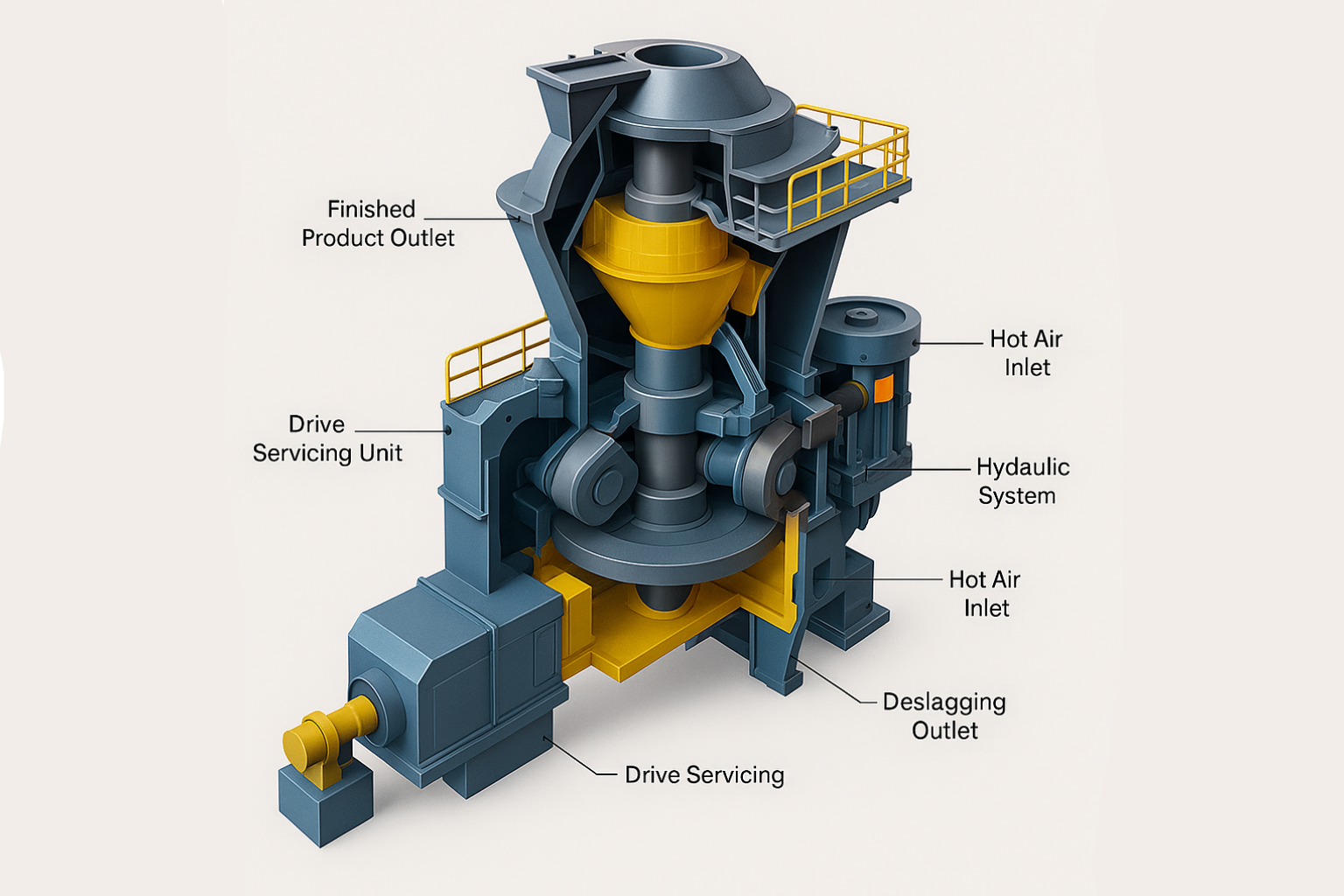

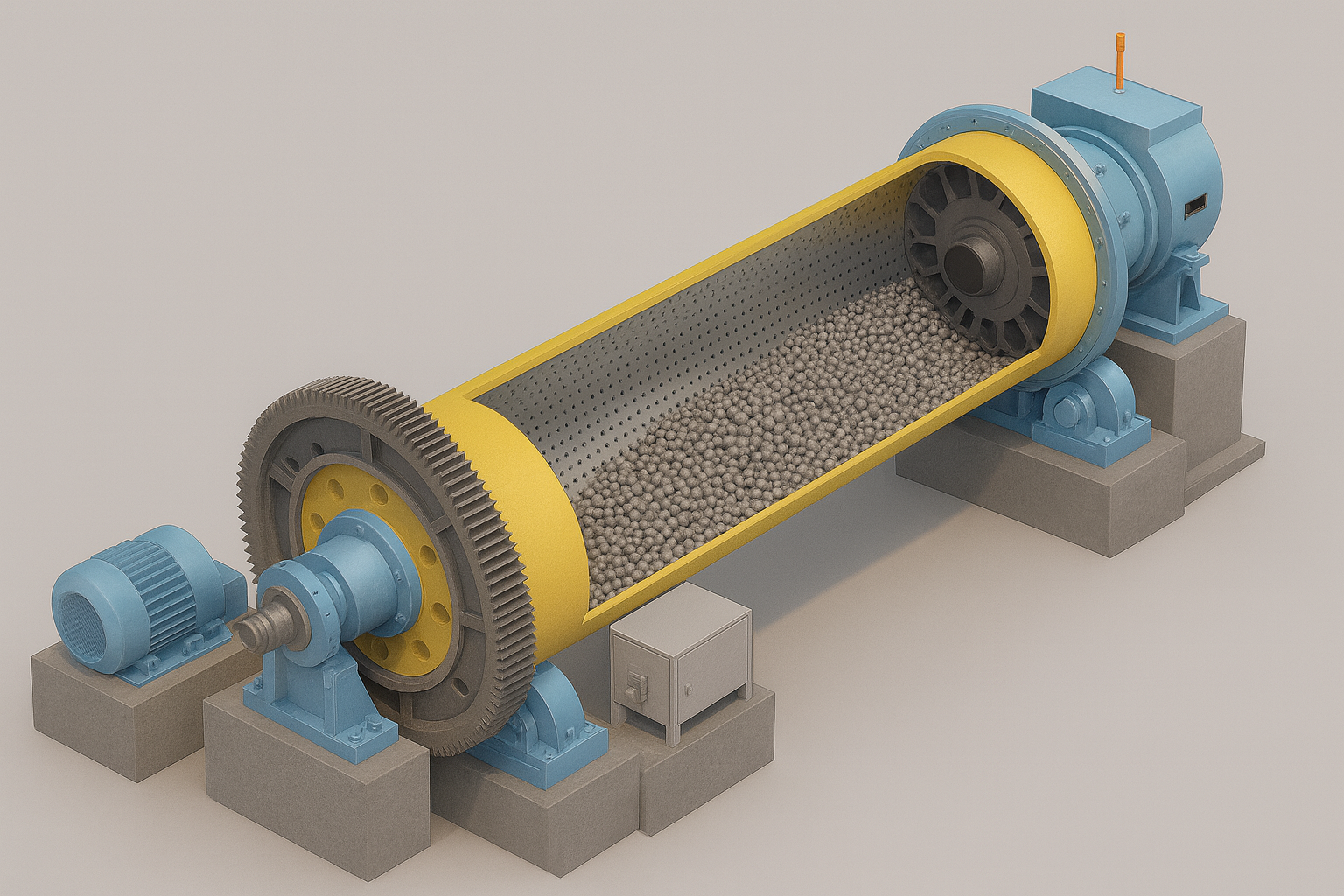

Abrasion-resistant liners for raw meal handling and classifier sections.

Raw mill ducts, rotary feeders, and separators encounter continuous sliding abrasion from dry meal and high-velocity particles. Arcoplate and ceramics extend component life and reduce efficiency loss caused by material build-up and erosion.

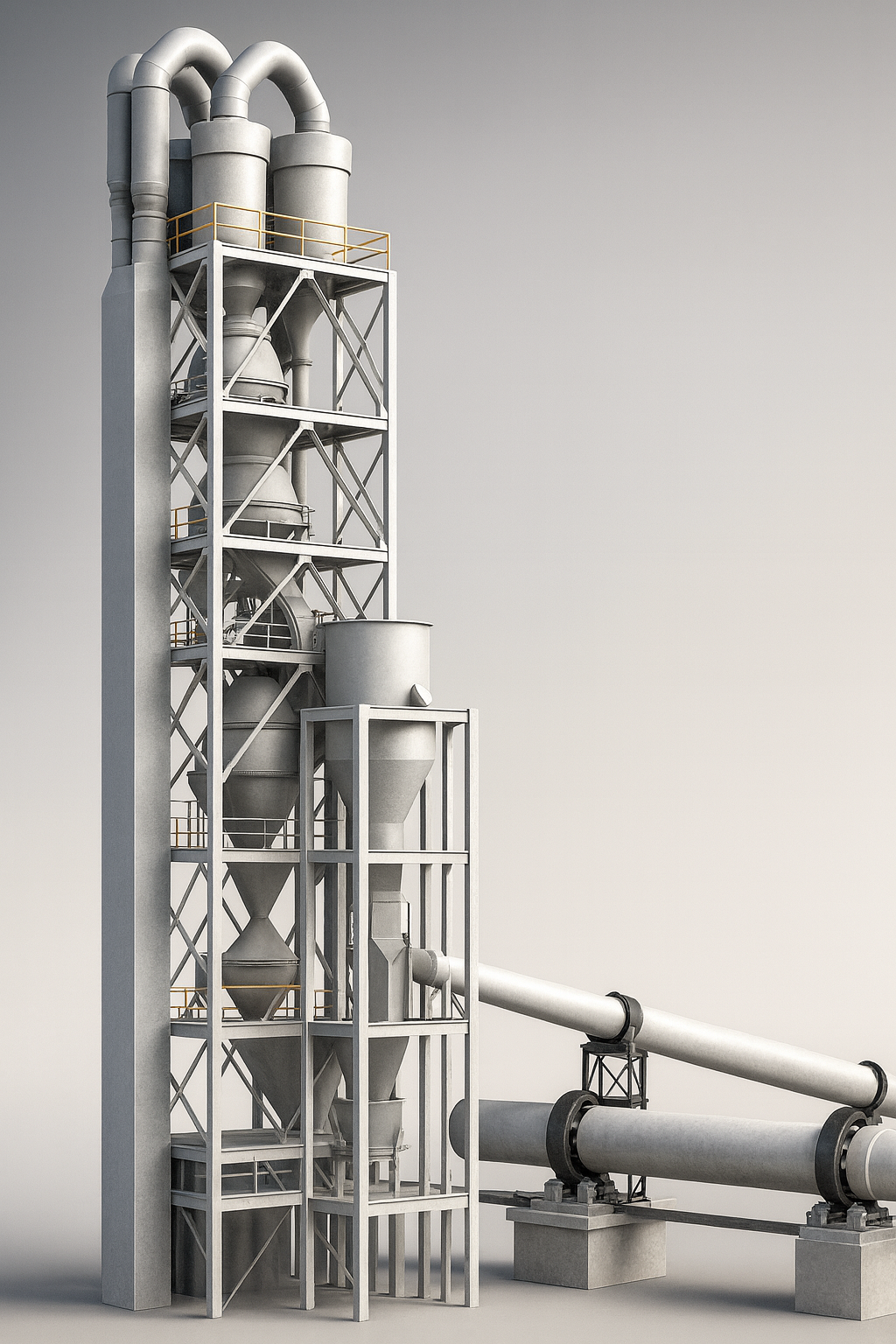

High-temperature wear protection for preheater and cyclone zones.

Cyclones and preheater areas face extreme temperatures and erosive dust-laden gases. Arcoplate high-temperature plates deliver stable performance under thermal shock while resisting fine particle abrasion in cone sections, dip tubes, and vortex finders.

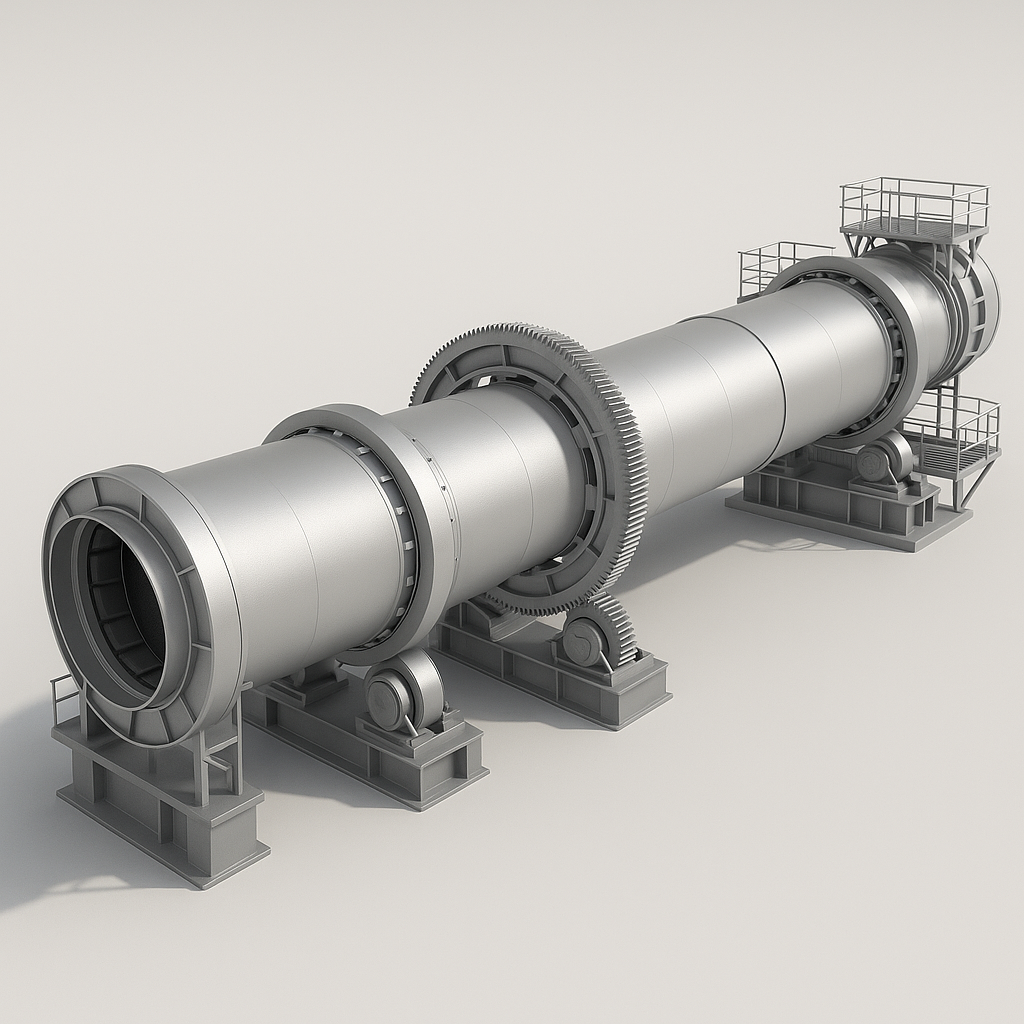

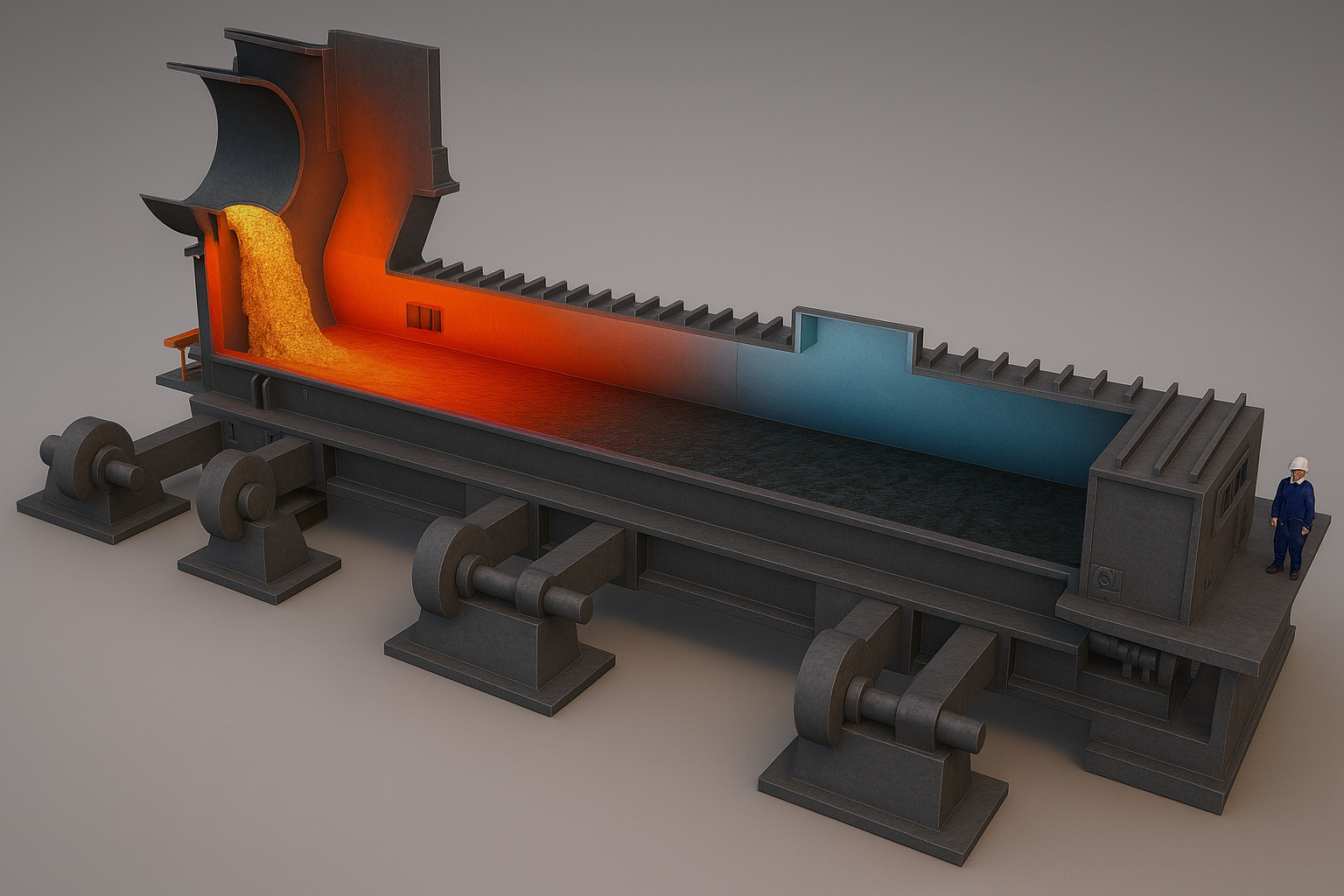

Heat-resistant liners for clinker discharge and cooler impact areas.

Kiln inlet and cooler zones experience severe abrasion from clinker, thermal shock, and impact loads. Arcoplate and ceramic liners offer reliable protection, improving availability and lowering downtime.

Durable protection for separator ducts, hoppers, and packing systems.

Fine cement particles cause rapid wear in separator ducts, rejects chutes, and packing plant hoppers. Arcoplate, PU, and ceramic liners ensure prolonged wear life and smooth material flow.

Durable protection for separator ducts, hoppers, and packing systems.

Fine cement particles cause rapid wear in separator ducts, rejects chutes, and packing plant hoppers. Arcoplate, PU, and ceramic liners ensure prolonged wear life and smooth material flow.