- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

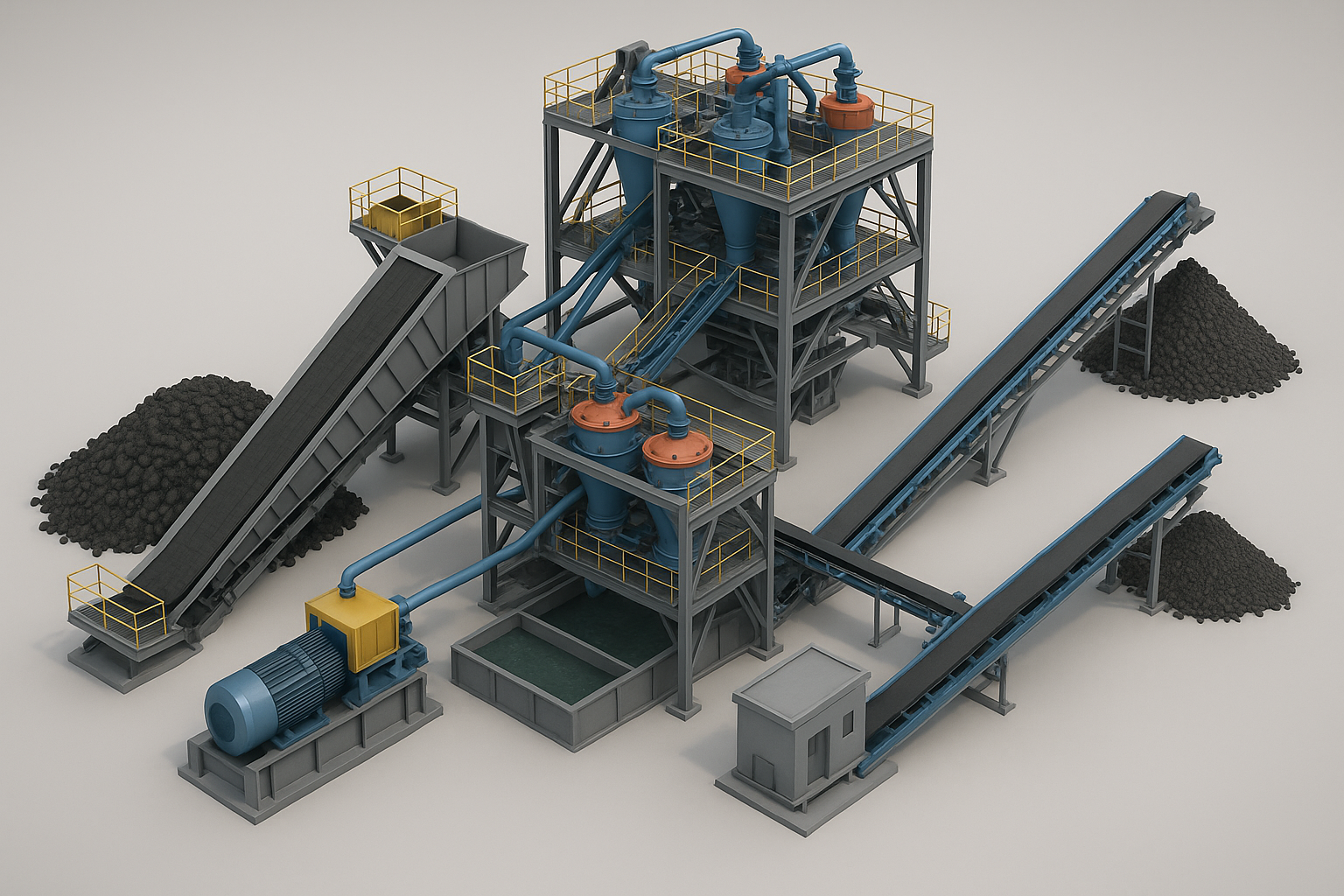

Wear solution mining

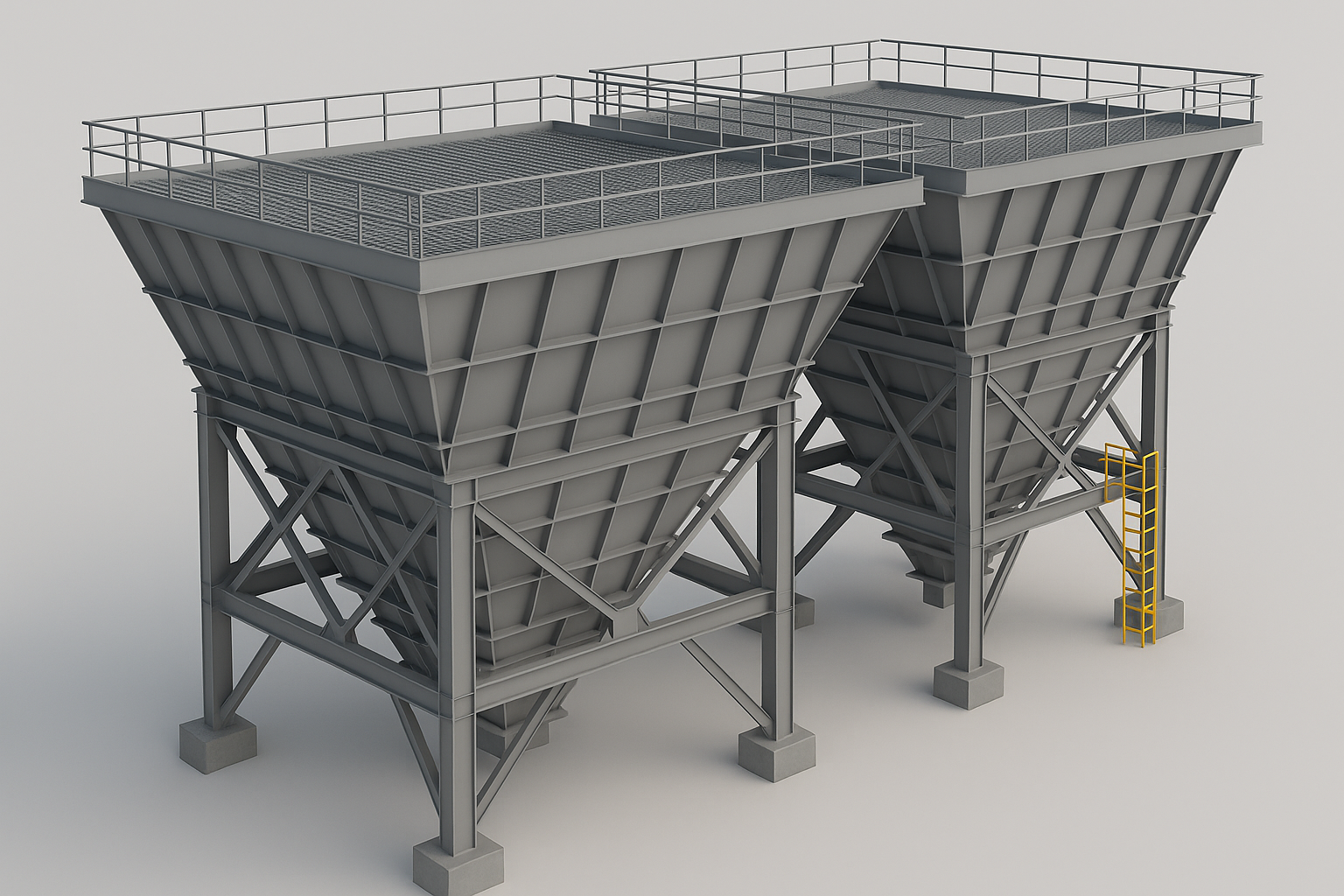

Impact-resistant liners for ROM dumping operations.

ROM hoppers face severe impact from oversized boulders during truck dumping. Arcoplate liners provide unmatched impact absorption and abrasion resistance, significantly increasing hopper lifespan.

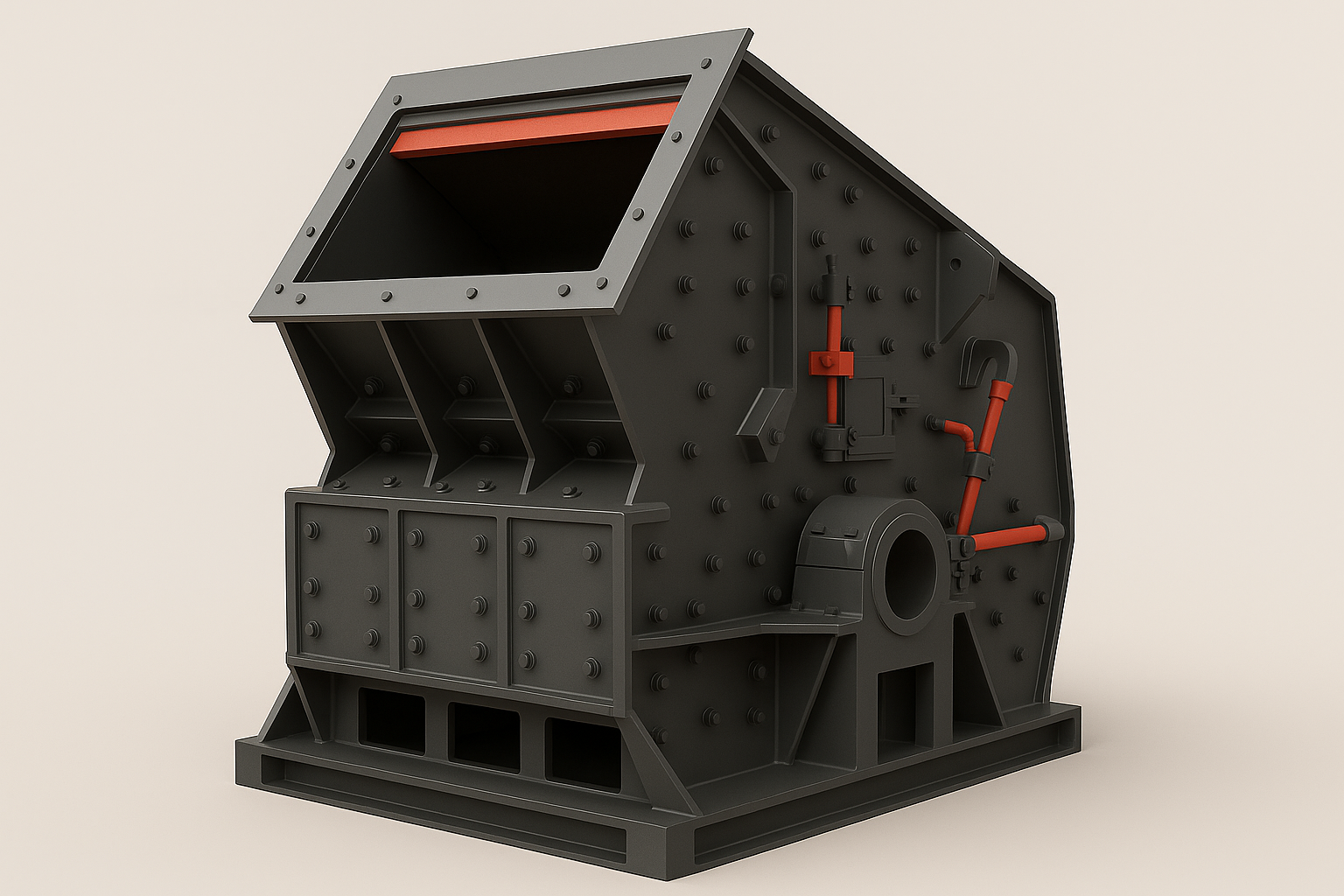

Wear solutions for primary and secondary crushers.

Crusher feed and discharge chutes experience high-impact and abrasive wear from hard rock. Arcoplate and ceramic liners enhance equipment reliability by resisting gouging, sliding abrasion, and particle impact.

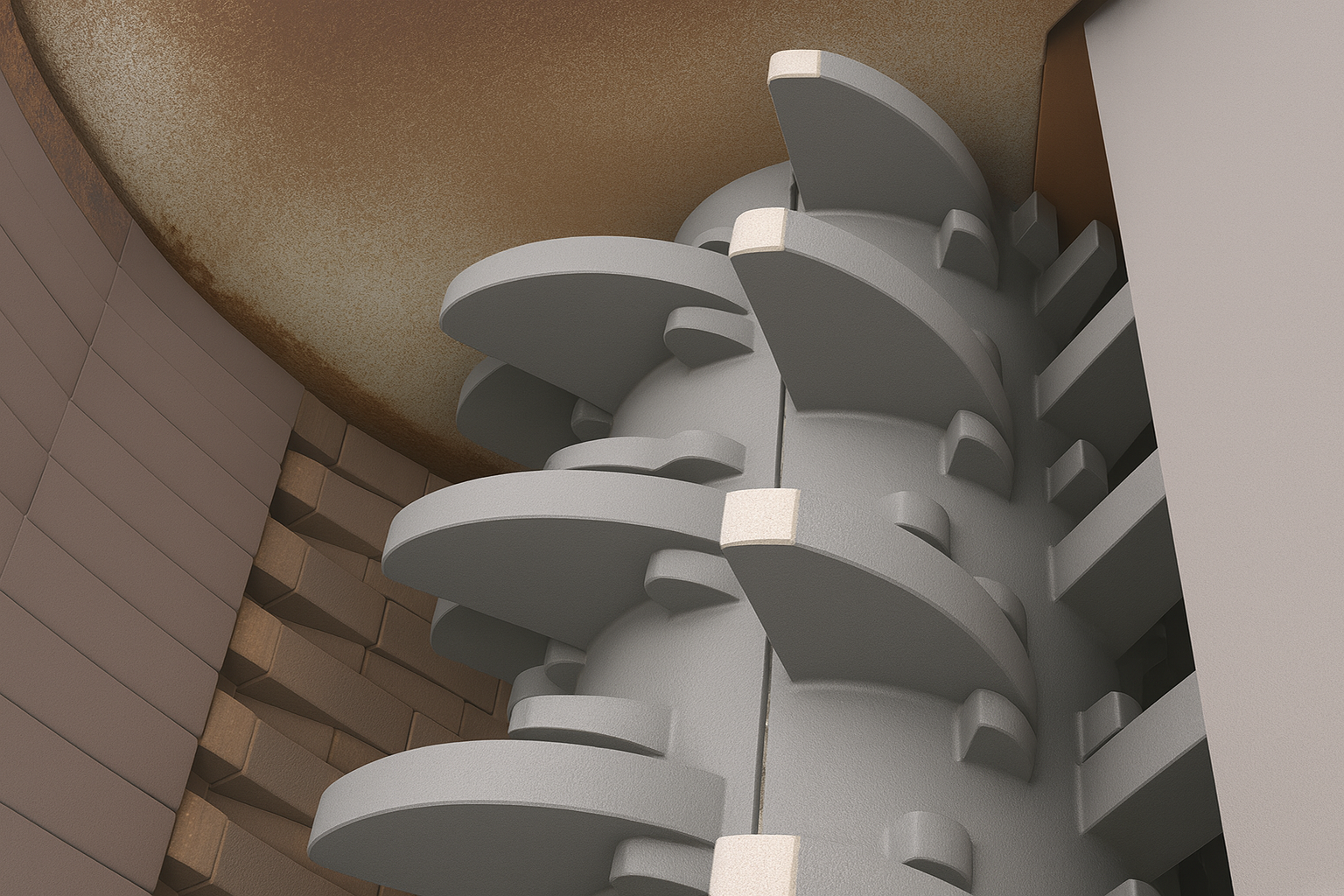

Wear protection for high-impact crushing zones and abrasive ore flow.

Abrasion-resistant liners for screens and underpans.

Screen underpans and chute liners handle sharp, abrasive material. PU and rubber-ceramic liners offer excellent wear resistance and vibration damping for stable screening performance.

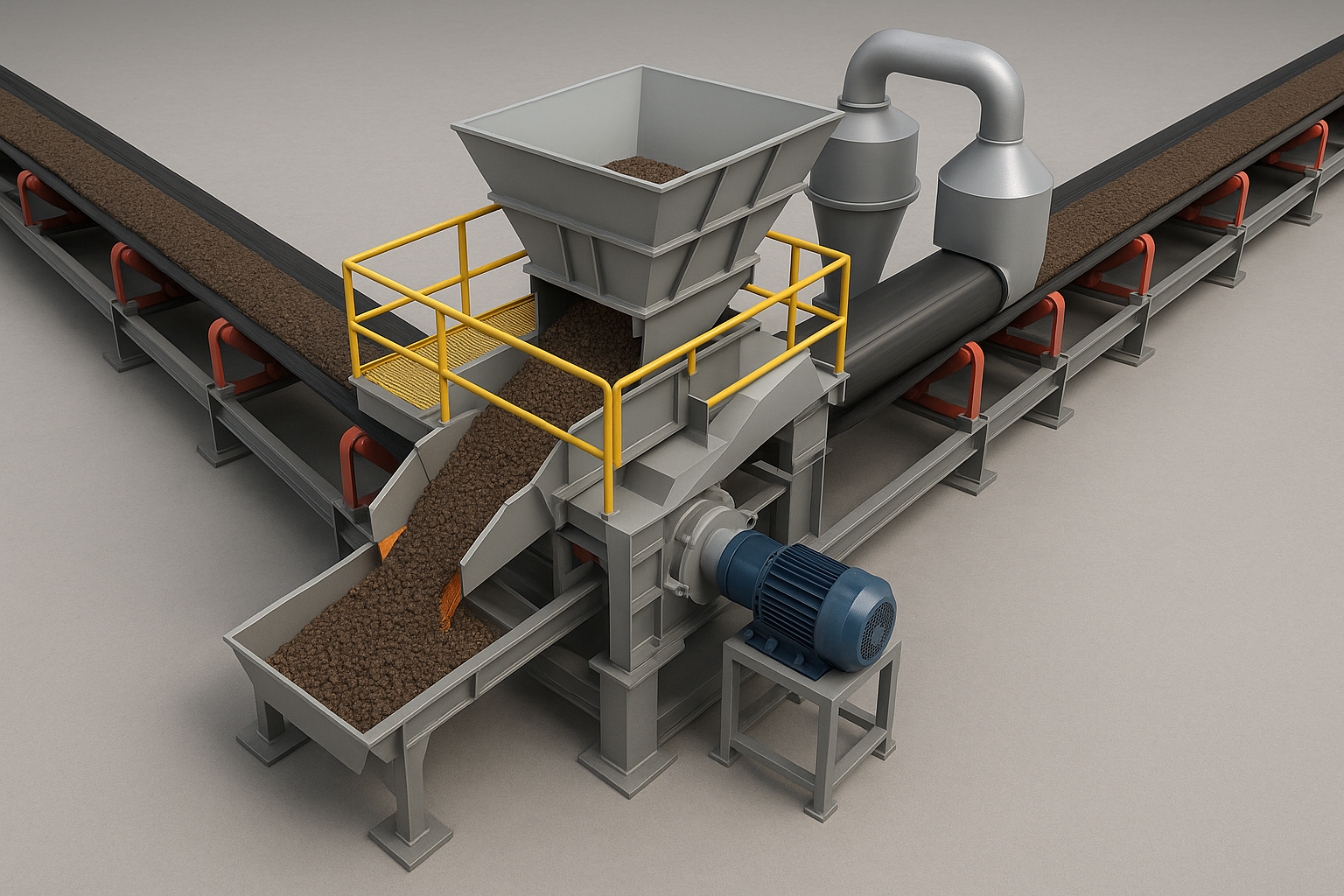

Heavy-duty liners for high-wear conveyor transfer zones.

Transfer points are among the highest wear areas due to continuous material impact and sliding. Arcoplate ensures long liner life, reducing downtime and spillage.

Corrosion and slurry-resistant liners for wet processing.

Wash plants handle abrasive slurry, fines, and high-velocity water flow. Rubber-ceramic and basalt liners prevent erosion and maintain structural integrity.