- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

Mobile Equipment

Protect your fleet. Perform more.

Heavy-duty wear solutions for high-impact digging.

Excavator buckets are exposed to continuous gouging, impact, and abrasive materials during digging, loading, and rock handling. ARTHA WearTech’s Arcoplate and wear bars protect critical wear zones such as bucket lips, side walls, and heel areas — improving penetration, reducing bucket rebuild frequency, and increasing productivity per cycle.

Enhanced durability for aggressive loading operations.

Loader buckets face constant sliding abrasion from ores, coal, aggregates, and minerals. Edge wear and corner wash-out are common failure modes. Our Arcoplate and ceramic composite liners reinforce large surface areas, reducing material loss and extending bucket life significantly — enabling high-efficiency loading with less downtime.

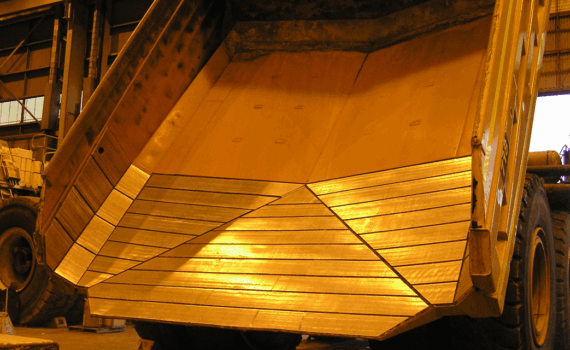

Wear-resistant lining for impact and sliding abrasion.

Dump truck bodies experience severe impact at loading and abrasive sliding during dumping. Conventional steel wears quickly, leading to high maintenance and body replacements. Artha WearTech’s Arcoplate and chute lining systems protect the floor and sidewalls — reducing carryback, lowering fuel use, and increasing payload lifecycle.

Extended blade life in harsh dozing environments

Dozers continuously push abrasive materials including ore, sinter, and overburden, causing rapid loss of blade edges and face. Our wear plates and ground-engaging protection systems prevent edge rounding and plate thinning — improving pushing efficiency and reducing frequent weld-repair downtime.

Impact and abrasion control for continuous mining.

Surface miners discharge high-velocity fragmented rock into chutes, creating intense impact wear and material gouging. Arcoplate and ceramic wear panels resist abrasive flow, keeping chutes free from hole-through failures — ensuring continuous miner output and improved operational availability.

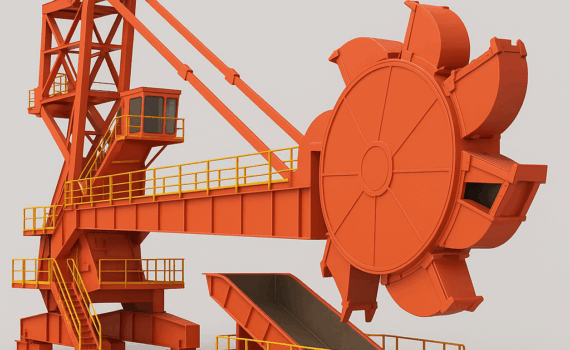

Reliable lining for bulk material flow handling.

Bucket wheel reclaimers deliver abrasive ores and coal at high speed, damaging chute liners through continuous sliding. Our advanced wear plates and ceramic tiles maintain smooth flow, reduce hang-ups and structural wear — enabling reclaimers to operate longer, with fewer unscheduled stoppages.

Severe wear protection for crushing feed zones.

Mobile crusher hoppers receive large, sharp run-of-mine ore dropped from height — creating intense impact and abrasion. Arcoplate liners armor the entire hopper, preventing cracks, floor blow-outs, and premature structural fatigue. Reduced downtime increases crusher throughput and reliability in mobile applications.