- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

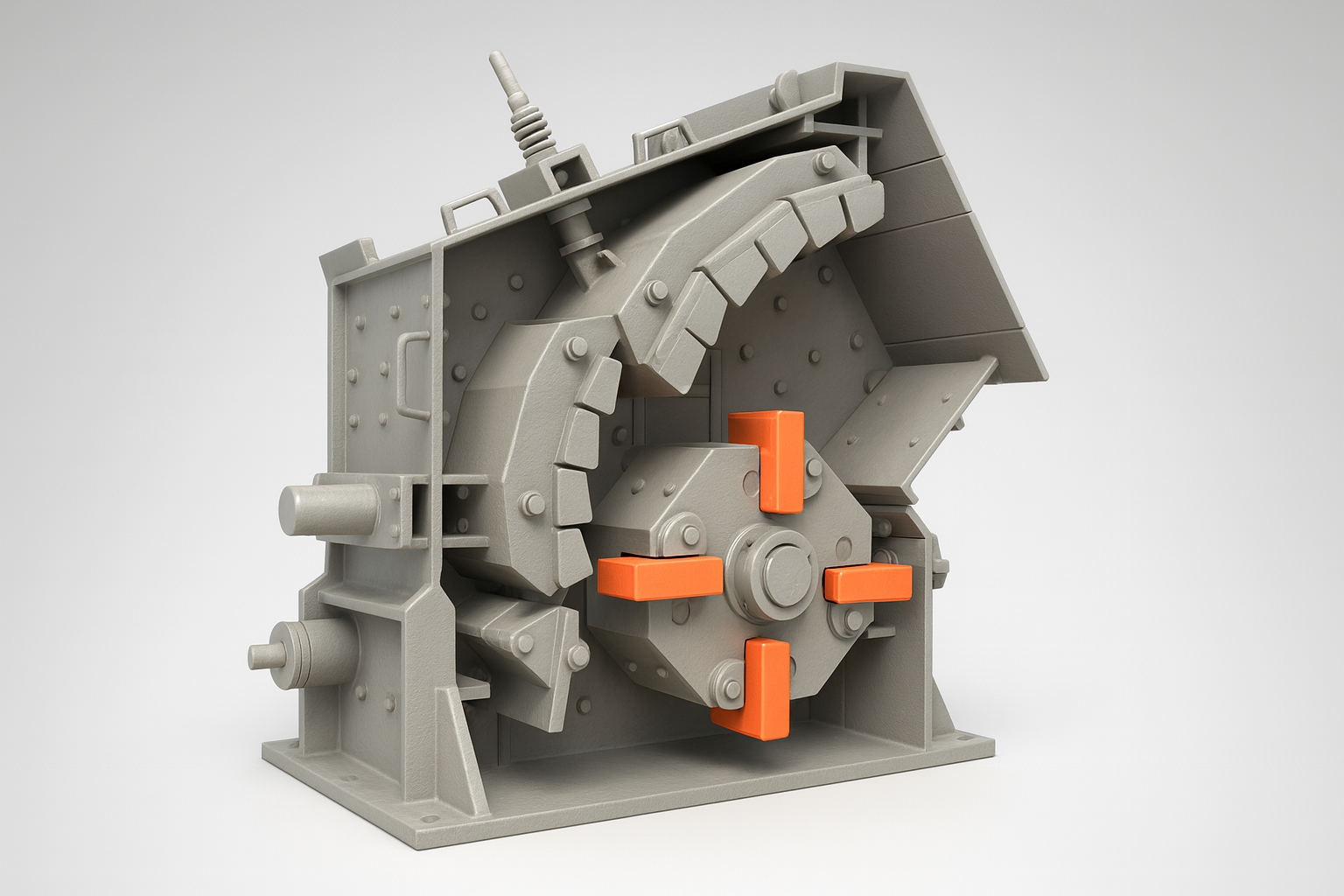

Limestone Crushing

Endure abrasion. Increase output.

Zone Introduction

The limestone crushing area is the first contact point for raw material arriving from the quarry. Large, hard, abrasive limestone boulders break down into smaller sizes for raw mill feeding. Any disruption here immediately affects the entire cement process. High impact forces and constant material movement create a severe wear environment.

Process Description

Run-of-quarry limestone contains silica and irregular sharp edges.

Material drops into hoppers and crushers generating:

- High-energy impact causing dents and cracks

- Continuous abrasion as limestone slides over surfaces

- Moisture + fines → Corrosion + slurry wear

- Vibration-induced fatigue failure in liners

Crushing works 24/7 → even thick liners wear thin quickly → risk of breakthrough holes.

Areas of Wear & Root Causes

Hopper floors → Heavy impact bulging

Feed and discharge chutes → Abrasive cutting

Crusher inlet zones → Gouging of liner plates

Performance Loss & Downtime Impact

Blockages slow down feed → Crusher overload

Chute leaks → Unsafe & high cleanup time

Frequent repairs → Lower availability & higher cost

Recommended Products & Benefits

- Impact + sliding abrasion protection

- Maintains structural strength under heavy rock drop

- Hard surface against abrasive fines