- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

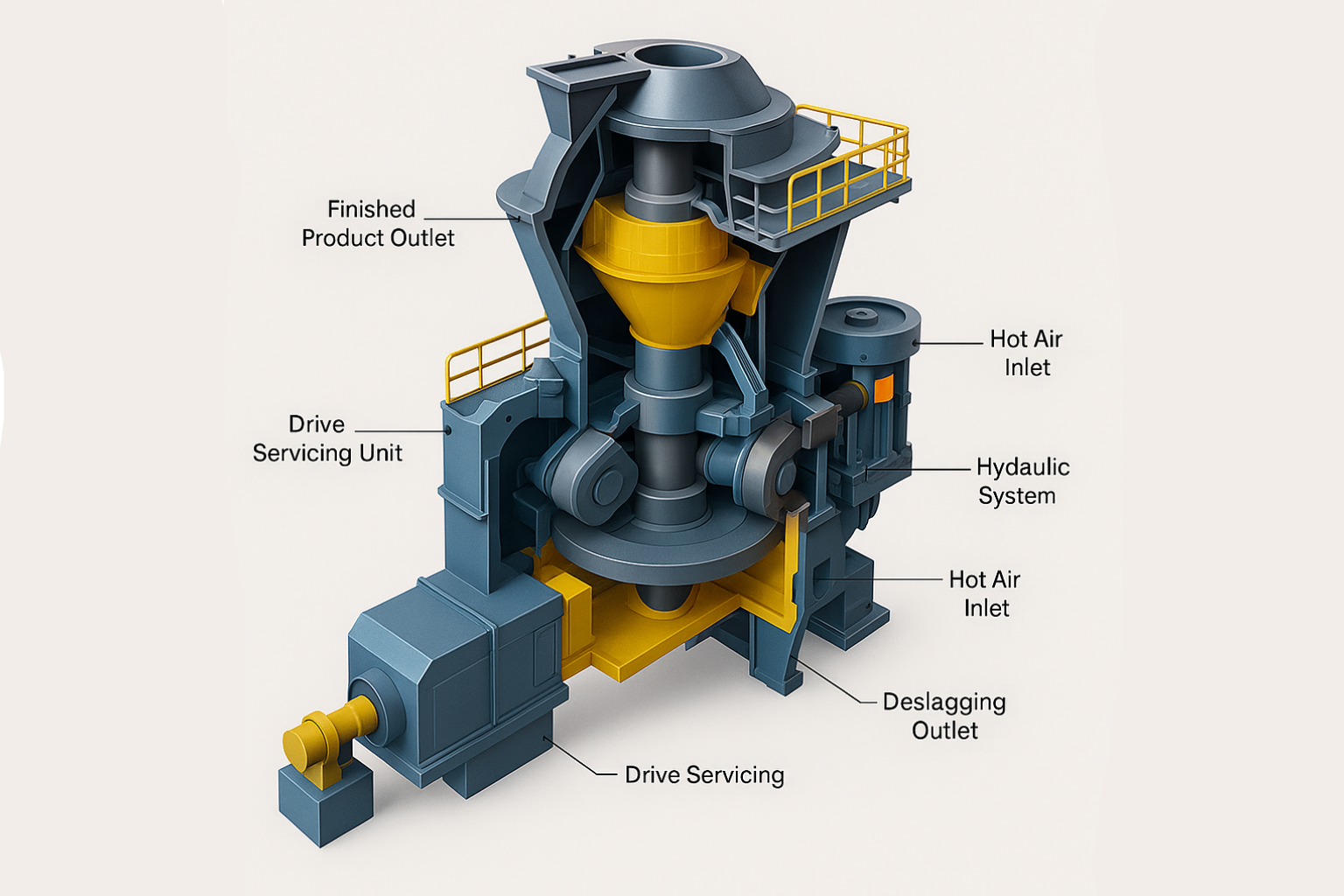

Raw Mill Feed Zones

Endure abrasion. Increase output.

Zone Introduction

Raw Mill efficiency directly influences kiln stability and final clinker quality.

Feed equipment must deliver uniform flow at constant rate.

Abrasion from fine raw material mix causes fast wear if unprotected.

Process Description

Mixed raw materials (limestone, shale, iron ore) pass through feed hoppers, rotary feeders and inlet chutes.

Wear mechanisms:

- Sliding abrasion from fines → Steel thinning

- Powder friction with moisture → Corrosion-abrasion

- Turbulent flow at bends → Localized groove wear

- Vibration → Weld cracking

Without proper liners, geometry changes → flow disturbance → process instability.

Areas of Wear & Root Causes

Inlet chutes & cone zones → Velocity erosion

Feed impact areas → Denting & gouging

Performance Loss & Downtime Impact

Fluctuating mill feed → Poor grinding efficiency

Higher kWh/ton consumption

Frequent liner change → Extended shutdowns

Recommended Products & Benefits

- Long life against fines abrasion

- Maintains smooth flow profiles

- Excellent resistance to high-speed fines