- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

- Home

- Industrial Solutions

- Partners

- Industry 4.0 / Digital Transformation

- Environmental Management

- Industry 4.0 / Digital Transformation

- Environmental Management

- Resources

- About Us

- Contact Us

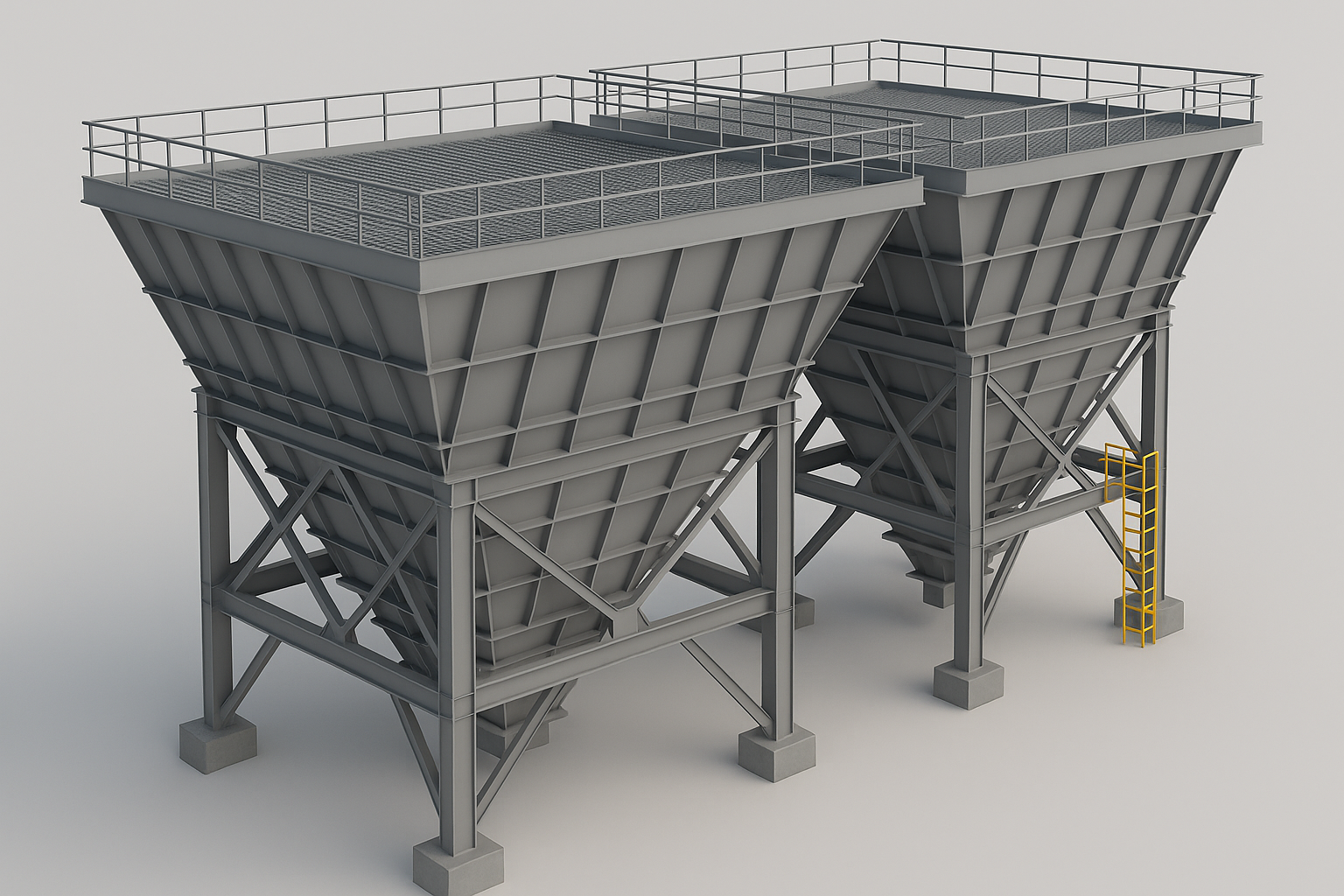

ROM Hopper — Run of Mine Hopper

Built for harsh mines. Proven to last.

Zone Introduction

ROM Hoppers are the very first receiving point for mine output.

Large, heavy rocks are dumped directly from trucks or shovels.

This area sees extreme impact + gouging + abrasion.

Any stoppage here halts the entire plant’s production flow.

Process Description

Run-of-mine ore contains varying hardness with silica and sharp cutting edges.

Hoppers continuously receive large boulders from high drop heights.

Wear mechanisms:

- Heavy impact loads → Denting, buckling & cracking

- Continuous abrasion from sliding → Steel thinning

- Sharp edges → Gouge marks & chips

- Vibration cycles → Fatigue failures

- Moisture converts fines → Slurry erosion

24/7 feeding → even thick steel plates lose integrity fast.

Areas of Wear & Root Causes

Hopper base plates → Impact & bending

Side wall liners → Sliding abrasion

Discharge lips → Turbulence erosion

Performance Loss & Downtime Impact

Breakthrough holes → Material spillage

Blockages → Loading delays → Lost productivity

Safety hazards for maintenance crew

Recommended Products & Benefits

- Impact + abrasion resistance

- Reinforcement for high strike zones

- Stronger structural life

- Lower unplanned maintenance